RH2 | Multi-material assemblies

The research activities relate to the development, characterisation and modelling of techniques for assembling materials of different kinds for long life spans in harsh environments, such as the marine environment. The use of new materials (thermoplastic composites for example), new grades of alloys, new surface preparations to reduce corrosion, etc. It is necessary to develop innovative assembly resources coupled with dimensioning methods which take account of the service conditions. Among the assembly resources, gluing and welding are the recognised techniques which have already been the subject of considerable study. However, the addition of new materials, combined with the desire to achieve higher performance in terms of assembly speed or mechanical characteristics, leads to the introduction of hybrid techniques requiring detailed studies.

Research areas

- Study and optimisation of the assembly processes

- Characterisation of the long term strength of assemblies

- Development of hybrid assembly techniques for hybrid/mixed structures

ARCAN test piece glued for tensile test

Know-how

Experimental methods

Development of original experimental systems:

- for the characterisation of assemblies

- thermophysical and mechanical properties at high temperature

- thermal and electrical contact resistance

- Fine instrumentation of test pieces (micro-thermocouple up to 12 µm, field strength measurements)

Characterisation of the initial and long-term behaviour:

- behaviour of the multi-material interfacial areas

- effects of the environment (temperature, relative humidity)

- rapid characterisation methods: accelerated ageing, mass/assembly relationship, self-heating

Digital methods

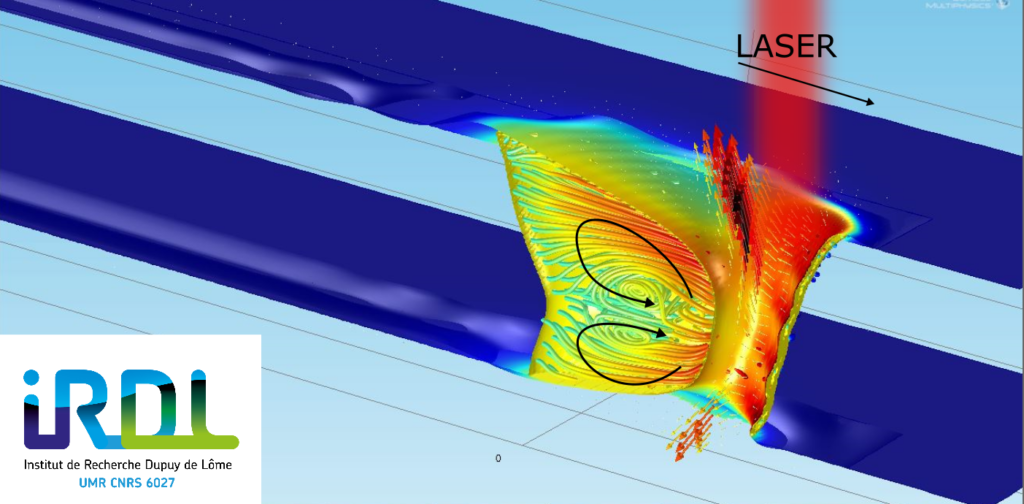

Digital simulation of assembly processes:

- digital simulation by finite elements of the assembly processes and heat treatment with dedicated software (COMSOL Multiphysics®, SYSWELD®, Forge2D®, Abaqus)

- thermo-metallurgical and thermo-mechanical behaviour in a welded assembly

- electro-thermal coupling with electrical and thermal contact resistance

- modelling of equivalent thermal sources,

- adhesive polymerisation modelling

- internal stresses in glue seals (initial state),

- magneto-thermo-hydrodynamic coupling

Digital simulation of mechanical behaviours:

- resistance and tenacity of an adhesive

- durability and ageing of glue seals

- cycling, fatigue

- Contribution of interfaces to mechanical behaviour

- Abaqus, Cast3M

Parameter and/or function estimation by inverse methods

Equipment

Applied to welded assemblies

- Gleeble 3500: thermo-metallurgical and thermo-mechanical characterisation machine,

- flash diffusivity meter, DSC, dilatometer,

- laser profilometer/roughness meter,

- electrical and thermal contact resistance measurement device

- microhardness tester and nanoindenter

- 3D tomography

- laser heating system (3 kW) in controlled conditions

- instrumented resistance welding (DC 10 kA, 5 kN)

- temperature measurement instruments:

- by contact (thermocouples up to 12 µm and data acquisition system 1 MHz)

- without contact (pyrometers, high-speed infrared camera (4 kHz))

Applied to glued assemblies

- Multi-axis loading devices:

- Arcan

- Traction/Compression – Torsion

- Scarf

- Cracking mountings (MMB and TDCB)

- Thermo-hydric conditioning enclosure/tanks

- Stereo Digital Image Correlation Devices (GOM)

- Monitoring by fibre optic Bragg grating (HBM FS22)

- Monitoring by acoustic emission